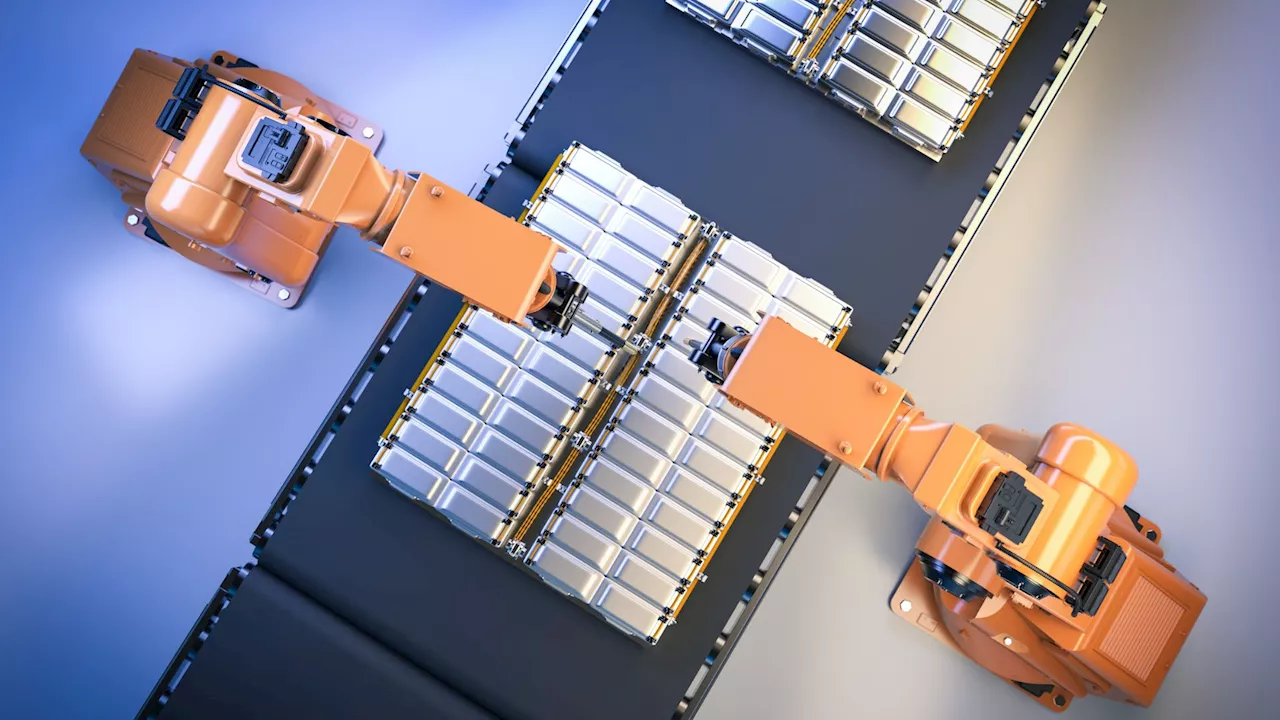

A new Stanford University study reveals that recycling lithium-ion batteries produces significantly fewer greenhouse gas emissions, consumes less water and energy compared to mining for new materials. The study highlights the potential of battery recycling to address the environmental challenges associated with battery production and contribute to a more sustainable future.

Researchers compared the environmental impacts of lithium-ion battery recycling to mining for new materials and found that recycling significantly outperforms mining in terms of greenhouse gas emissions , water use, and energy use. Recycling lithium-ion batteries to recover their critical metals has significantly lower environmental impacts than mining virgin metals, according to a new Stanford University lifecycle analysis published in Nature Communications.

On a large scale, recycling could also help relieve the long-term supply insecurity -- physically and geopolitically -- of critical battery minerals. Lithium-ion battery recyclers source materials from two main streams: defective scrap material from battery manufacturers, and so-called 'dead' batteries, mostly collected from workplaces. The recycling process extracts lithium, nickel, cobalt, copper, manganese, and aluminum from these sources. The study quantified the environmental footprint of this recycling process, and found it emits less than half the greenhouse gases (GHGs) of conventional mining and refinement of these metals and uses about one-fourth of the water and energy of mining new metals. The environmental benefits are even greater for the scrap stream, which comprised about 90% of the recycled supply studied, coming in at: 19% of the GHG emissions of mining and processing, 12% of the water use, and 11% of the energy use. While it was not specifically measured, reduced energy use also correlates with less air pollutants like soot and sulfur. 'This study tells us that we can design the future of battery recycling to optimize the environmental benefits. We can write the script,' said William Tarpeh (BS '12), assistant professor of chemical engineering in the School of Engineering and the study's senior author. Battery recycling's environmental impacts depend heavily on the processing facility's location and electricity source. 'A battery recycling plant in regions that rely heavily on electricity generated by burning coal would see a diminished climate advantage,' said Samantha Bunke, a PhD student at Stanford and one of the study's three lead investigators. 'On the other hand, fresh-water shortages in regions with cleaner electricity are a great concern,' added Bunke. Most of the study's data for battery recycling came from Redwood Materials in Nevada -- North America's largest industrial-scale lithium-ion battery recycling facility -- which benefits from the western U.S.'s cleaner energy mix, which includes hydropower, geothermal, and solar. Transportation is also a crucial factor. In the mining and processing of cobalt, for example, 80% of the global supply is mined in the Democratic Republic of the Congo. Then, 75% of the cobalt supply for batteries travels by road, rail, and sea to China for refining. Meanwhile, most of the global supply of lithium is mined in Australia and Chile. Most of that supply also makes its way to China. The equivalent process for battery recycling is collecting used batteries and scrap, which must then be transported to the recycler. 'We determined that the total transport distance for conventional mining and refining of just the active metals in a battery averages about 35,000 miles (57,000 kilometers). That's like going around the world one and a half times,' said Michael Machala, PhD '17, also a lead author of the study. 'Our estimated total transport of used batteries from your cell phone or an EV to a hypothetical refinement facility in California was around 140 miles (225 kilometers),' added Machala, who was a postdoctoral scholar at Stanford's Precourt Institute for Energy at the time of research and is now a staff scientist for the Toyota Research Institute. This distance was based on presumed optimal locations for future refining facilities amid ample U.S. recyclable batteries. Redwood's environmental outcomes do not represent the nascent battery recycling industry's overall environmental performance for recycling used batteries. Conventional pyrometallurgy, a key refining step, is very energy intensive, usually requiring temperatures of more than 2,550 degrees Fahrenheit (1,400 degrees Celsius). Redwood, however, has patented a process called 'reductive calcination,' which requires considerably lower temperatures, does not use fossil fuels, and yields more lithium than conventional methods. 'Other pyrometallurgical processes similar to Redwood's are emerging in labs that also operate at moderate temperatures and don't burn fossil fuels,' said the third lead author, Xi Chen, a postdoctoral scholar at Stanford during the time of research and now an assistant professor at City University of Hong Kong. 'Every time we spoke about our research, companies would ask us questions and incorporate what we were finding into more efficient practices,' added Chen.'This study can inform the scale-up of battery recycling companies, like the importance of picking good locations for new facilitie

Lithium-Ion Batteries Recycling Mining Greenhouse Gas Emissions Sustainability Environmental Impact

United States Latest News, United States Headlines

Similar News:You can also read news stories similar to this one that we have collected from other news sources.

New Coating Enables Lithium-ion Batteries to Operate at Higher VoltagesResearchers at the Paul Scherrer Institute (PSI) have developed a novel surface coating that allows lithium-ion batteries to operate at higher voltages, potentially increasing energy density and performance for electric vehicles.

New Coating Enables Lithium-ion Batteries to Operate at Higher VoltagesResearchers at the Paul Scherrer Institute (PSI) have developed a novel surface coating that allows lithium-ion batteries to operate at higher voltages, potentially increasing energy density and performance for electric vehicles.

Read more »

Massive Fire Engulfs Californian Power Plant With Lithium-Ion BatteriesA large fire erupted at the Moss Landing power plant in California, threatening one of the world's biggest battery energy storage facilities. The blaze, which began in a building housing lithium-ion batteries, prompted evacuations in the surrounding area. Fire officials are allowing the building and batteries to burn, despite the potential for an extremely difficult-to-extinguish fire. Hundreds of people have been evacuated, and a section of Highway 1 has been closed.

Massive Fire Engulfs Californian Power Plant With Lithium-Ion BatteriesA large fire erupted at the Moss Landing power plant in California, threatening one of the world's biggest battery energy storage facilities. The blaze, which began in a building housing lithium-ion batteries, prompted evacuations in the surrounding area. Fire officials are allowing the building and batteries to burn, despite the potential for an extremely difficult-to-extinguish fire. Hundreds of people have been evacuated, and a section of Highway 1 has been closed.

Read more »

Lithium-Ion Batteries Complicate Cleanup Efforts After California WildfiresThe recent wildfires in California have caused extensive damage, with thousands of homes destroyed. Cleanup efforts are being hampered by the presence of burnt-out lithium-ion batteries from electric and hybrid vehicles, as well as home battery systems. These batteries pose a significant risk due to their toxic materials and require specialized removal, delaying the return of fire victims to their properties.

Lithium-Ion Batteries Complicate Cleanup Efforts After California WildfiresThe recent wildfires in California have caused extensive damage, with thousands of homes destroyed. Cleanup efforts are being hampered by the presence of burnt-out lithium-ion batteries from electric and hybrid vehicles, as well as home battery systems. These batteries pose a significant risk due to their toxic materials and require specialized removal, delaying the return of fire victims to their properties.

Read more »

Korean Researchers Develop High-Capacity Lithium-Sulfur Batteries for Urban Air MobilityResearchers at the Korea Electrotechnology Research Institute (KERI) have overcome a major hurdle in lithium-sulfur battery technology, paving the way for their use in urban air mobility (UAM). The team developed large-area, high-capacity prototypes that address the issue of polysulfide shuttling, a key challenge hindering the performance and lifespan of these batteries.

Korean Researchers Develop High-Capacity Lithium-Sulfur Batteries for Urban Air MobilityResearchers at the Korea Electrotechnology Research Institute (KERI) have overcome a major hurdle in lithium-sulfur battery technology, paving the way for their use in urban air mobility (UAM). The team developed large-area, high-capacity prototypes that address the issue of polysulfide shuttling, a key challenge hindering the performance and lifespan of these batteries.

Read more »

NYC Firefighters Encounter Frozen Hydrant, E-Bikes, and Lithium-ion Batteries After Flushing FireNew York City firefighters responded to a fire in the Flushing section of Queens on Friday morning, encountering a frozen hydrant, multiple e-bikes, and lithium-ion batteries. The FDNY shared details about the incident.

NYC Firefighters Encounter Frozen Hydrant, E-Bikes, and Lithium-ion Batteries After Flushing FireNew York City firefighters responded to a fire in the Flushing section of Queens on Friday morning, encountering a frozen hydrant, multiple e-bikes, and lithium-ion batteries. The FDNY shared details about the incident.

Read more »

Wildfire Debris Cleanup in Los Angeles Faces Challenge with Large Number of Damaged Lithium-ion BatteriesCleanup efforts in Los Angeles neighborhoods ravaged by wildfires are encountering a major hurdle: the widespread presence of damaged lithium-ion batteries. These batteries, found in electric vehicles, power banks, and various electronic devices, pose a significant fire hazard when damaged. The EPA is deploying specialized teams to safely collect and neutralize these batteries, a process expected to take months.

Wildfire Debris Cleanup in Los Angeles Faces Challenge with Large Number of Damaged Lithium-ion BatteriesCleanup efforts in Los Angeles neighborhoods ravaged by wildfires are encountering a major hurdle: the widespread presence of damaged lithium-ion batteries. These batteries, found in electric vehicles, power banks, and various electronic devices, pose a significant fire hazard when damaged. The EPA is deploying specialized teams to safely collect and neutralize these batteries, a process expected to take months.

Read more »